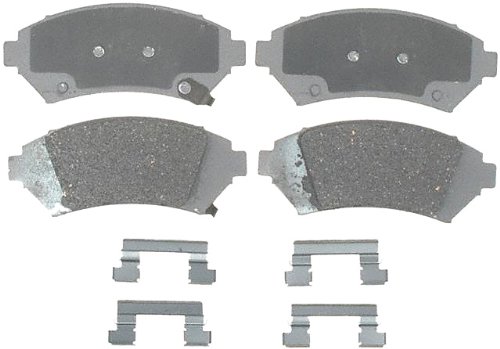

ACDelco 14D465C Advantage Front Ceramic Disc Brake Pad Set Review

ACDelco 14D465C Advantage Front Ceramic Disc Brake Pad Set Feature

- ACDelco brakes are independantly tested and D3EA certified to meet the industry's highest level of braking performance

- Manufactured using ceramic and nonferrous materials for inmproved heat dissipation and quiet operation

- Produce less dust than semi-metallic brake pads to keep your wheels cleaner

- Limited Lifetime Warranty

- ACDelco is an Original Equipment (OE) supplier and has the experience engineering and manufacturing components that achieve the highest quality standards required by vehicle manufacturers

Features and Benefits

Ceramic brake pads are generally quieter and offer more durability than semi-metallic pads. D3EA tested and approved. Produce less dust than semi-metallic brake pads. Manufactured using ceramic and nonferrous materials. ACDelco Professional DuraStop brake pads and shoes carry a limited lifetime warranty*

Durability ACDelco Professional DuraStop Brakes are designed to help resist corrosion and premature wear

Quiet : You won't hear much from these high-quality brakes parts

Quality Assurance : ACDelco Professional DuraStop Brakes are the most thoroughly, independently tested brakes on the aftermarket. ACDelco submits its brake products through a range of test methods, including D3EA and SAE J2784 for braking effectiveness, along with Noise/Vibration/Harshness (NVH) and durability/wear testing. This allows us to deliver the high-quality product that an ACDelco customer expects. No manufacturer tests or audits its replacement brake products to the level of ACDelco. Read about Dual Dynamometer Differential Effectiveness Analysis (D3EA) and SAE J2784.

Warranty : ACDelco Professional DuraStop brake pads and shoes carry a limited lifetime warranty.* All other Professional DuraStop brake products carry a 12 month/12,000 mile mimited warranty from sale or installation.*

*To the original retail purchaser. Parts only; installation not included. See your local retailer or independent service center that offers ACDelco parts for details.

Function & Signs of Wear

Find out more about ACDelco Professional DuraStop Ceramic Brake Pads and how they fit into the Brakes System with the product facts below.

Brake Pads:

FUNCTION: Flat pads with frictional materials contact the rotor to help slow or stop the vehicle (disc brakes)

SIGNS OF WEAR: Chirping, grinding or squealing noise, difficulty stopping the vehicle

Did You Know?

When you step on your brake pedal, you command a stopping force 10 times as powerful as the force that puts the car in motion. The brakes system can exert as much as 1,000 pounds (450 kg) of hydraulic pressure on each of the four brakes.

What It Does

The Brake System applies frictional force to the wheels to slow or stop the vehicle.

Service & Maintenance

The following inspections and maintenance procedures can help prevent potential brake problems:

Check brake fluid level at every oil change. Replace fluid according to Owner's Manual recommendations.

Calipers and wheel cylinders should be checked every brake inspection and serviced or replaced as required.

Inspect the brake lines for rust, punctures or visible leaks (you may be able to do this, but consult a qualified technician if necessary)

The following should be conducted by a qualified technician:

- Inspection of the brake hoses for brittleness or cracking

- Inspection of brake lining and pads for wear or contamination by brake fluid or grease

- Inspection of wheel bearings and grease seals

- Parking brake adjustments (as needed)

Used rotors can be machined provided minimum thickness can be maintained:

Before you machine rotors, make sure the lathe is clean, within specs and has sharp tool bits.

After completing the finish cut, sand both sides of the rotor for one minute per side using a sanding block and 130- to 150-grit sandpaper to obtain a non-directional finish.

After sanding, wash the rotor with dish soap and water. DO NOT clean the rotor with brake cleaner/solvent-based product.

Thoroughly clean the calipers, caliper slide sand hardware. Remove all dirt, rust and grease.

DuraStop brake tech tips:

Lubricate caliper slides, shims and rubber components.

Use ACDelco silicone-based lubricant or equivalent before installation. ACDelcolubricant is rated at 2,000F.

DO NOT use a petroleum-based or spray adhesive product:

Lubricate all hardware rubber components and all metal-to-metal contact points.

Give caliper slides and disc pad shims/insulators a thin film of lubricant. This will allow the shim to withstand normal brake pad movement without damage to the shim. Additionally, this helps dampen vibration. Make sure the disc pads are tight in the caliper and torque the caliper to the housing. Check the adjustment of the rear brakes. Adjust if necessary. After cleaning all wheel-hub mating surfaces, install the wheels. Make sure they are torqued to manufacturer's specifications.

D3EA tested and approved.