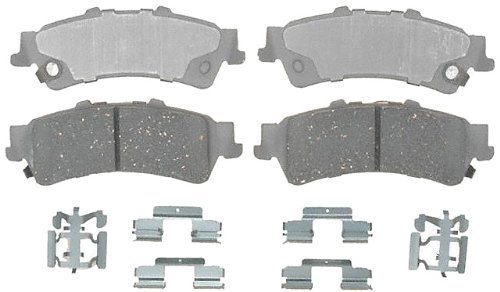

Akebono ACT906A ProACT Ultra-Premium Ceramic Brake Pad Set Review

Akebono ACT906A ProACT Ultra-Premium Ceramic Brake Pad Set Feature

- Ultimate upgrade for OE semi-metallic, organic and low-metallic brake pads

- Ultra-Quiet - controls noise, vibration and harshness levels

- Superior initial effectiveness with no required break-in period

- Extremely rotor friendly for longer rotor life

- Vehicle optimized ceramic formula for superior performance

Engineered to precise Original Equipment (OE) standards, Akebono ProACT Ultra-Premium ceramic brake pads provide the ultimate braking experience suitable for the vast majority of motorists. Designed using vehicle-optimized friction formulations aimed at eliminating noise, vibration and harshness (NVH) and severely limiting wheel dust, while increasing durability and smooth braking events, they are the best replacement for restoring OE ceramic pad performance, as well as upgrading from conventional pads.

Cruising along the interstate, creeping through rush hour traffic or navigating through your neighborhood, you count on your brakes to stop your vehicle every time with smooth, quiet assurance. Why possibly compromise braking performance just because it is time to replace your Brake Pads? Today, motorists have an option to restore OE performance. Akebono Pro-ACT Ultra Premium ceramic brake pads are the aftermarket's only OE validated, application-specific friction formulations. Akebono knows the precise definition of OE-Quality as determined by the Original Equipment Manufacturers, because Akebono bids on all vehicle platforms and models years in North America. In addition to dramatically quieter braking, Pro-ACT Ceramic Pads provide best-in-class braking performance, including enhanced initial effectiveness (no break-in required), high resistance to fade, consistent brake pedal feel and ultra-low dusting for cleaner wheels and tires. Ceramic technology also causes minimal wear on brake rotors. Taken together these factors guarantee that Akebono's Pro-ACT Ultra Premium brake pads provide the ultimate braking experience-reaching new performance levels or better. Akebono's Research & Development Being the largest brake manufacturer in the world gives Akebono a unique advantage: an exclusive Original Equipment experience and expertise backed by the most comprehensive Research & Development in the industry. That fierce pursuit of unfailing quality and safety assures that Akebono continues to be the innovating leader of braking technology. Key Features:

4-Akebono ProACT Ultra-Premium ceramic brake pads. About Akebono Akebono was established in Japan in 1929, at a time when the Japanese automobile industry had only produced 400 vehicles. Since then, keeping pace with the onset of motorization, Akebono has entered the domestic and overseas markets as brake experts. Committed to precision, Akebono refuses to cut corners on safety and will only implement best practices in their operations. This time-tested approach has resulted in proven quality control techniques that guarantee minimal process variation in all phases of production. Embraced throughout the organization, this approach enables the company to consistently achieve nearly zero defects per million parts produced. |